Membranes are used to separate, concentrate, remove, and clarify components from a fluid solution. They are a part of the processing unit in almost every industrial sector, especially in food, chemical, and biotechnological sectors. Few of the industrial examples are:

- juice, wine clarification,

- cleaning and recycling the industrial water (Effluent Treatment Plants, i.e. ETP) ,

- in automotive industry they are used in paint and adhesive clarification e.g. Fiat, Ferrari use microfiltration to produce high quality body paints.

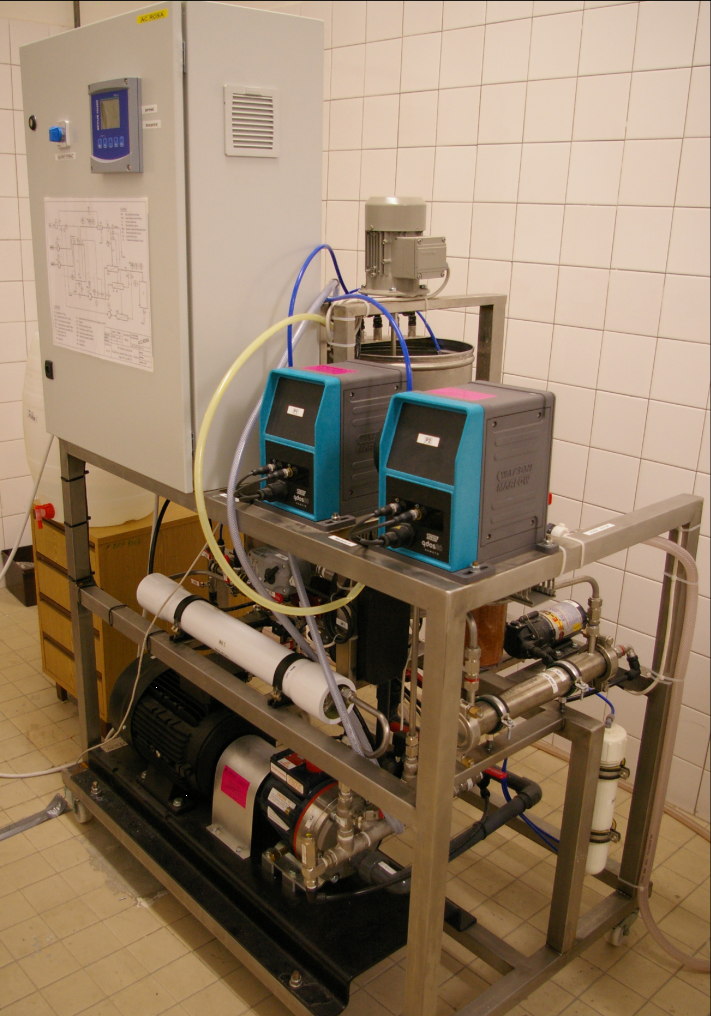

The solution containing initial concentration of different components is added to the feed tank. The pump then pressurizes the feed towards the membrane. The solution separates into two streams. The concentrated/rejected one is called retentate and comprises concentrated bigger solutes. The stream that is allowed to pass through the membrane is called permeate, and it basically comprises the smaller solutes. The current experiments being conducted are for concentrating lactose, and reducing salts. The objective is to implement the designed optimal strategy [1] and compare it with the classical industrial strategies. All of the experiments are conducted at constant temperature and pressure [2]. The completed and on-going projects can be referred from the institute's webpage. Besides, new projects could be developed according to student's interests, where they can learn how to operate e.g. PLC devices.

[1] Jelemenský, M. – Sharma, A. – Paulen, R. – Fikar, M. (2016). Time-optimal control of diafiltration processes in the presence of membrane fouling. Computers & Chemical Engineering , 343-351.

[2] Sharma, A. – Jelemenský, M. – Valo, R. – Kaluz, M. – Fikar, M. (2016). Process Control Education using a Laboratory Separation Process. 11th IFAC Symposium on Advances in Control Education (pp. 4-9). Bratislava: Elsevier.

Text by our collegue, Ayush Sharma.