A mathematical model has an important use in industry, by simulating it we can see how our process behaves under different operating conditions without having to make a change to the actual equipment. By comparing the mathematical model with the real system, we can observe anomalous process behavior that can serve as a failure indicator. It also helps us to identify the problem and solve it efficiently.

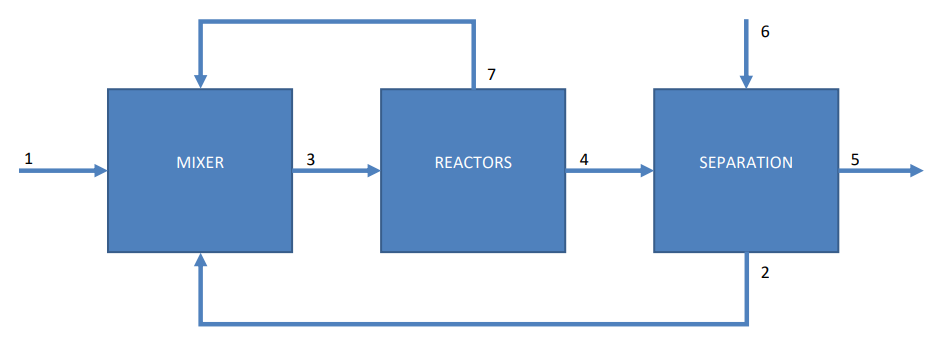

In this work, my task was to create a simplified mathematical model of an alkylation unit using P&ID diagrams and data obtained from the process. I divided the mathematical model into three parts (Figure: 1). Mixing, reaction, and separation part. The reaction part consists of three reactors where the chemical reaction of olefins with isobutane takes place to form alkylate.

Simulation results:

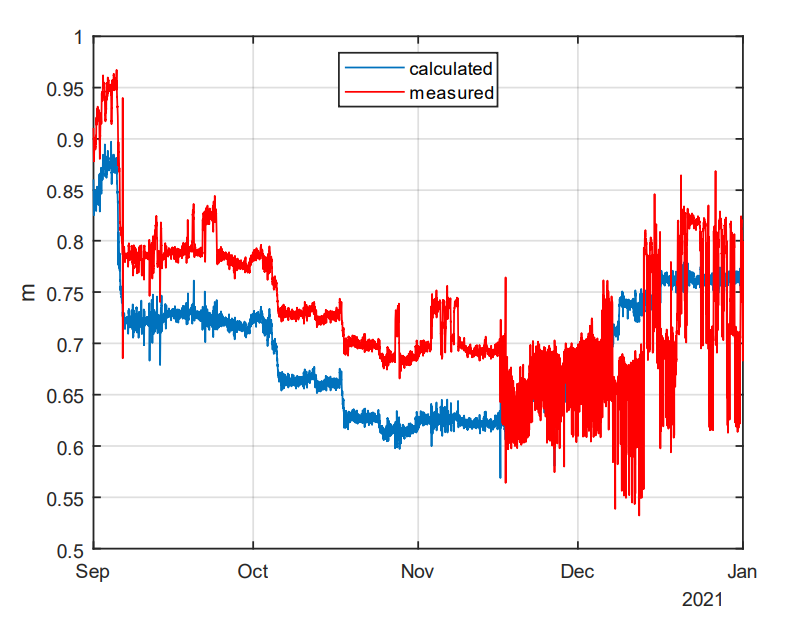

In this figure, we can see that the measured data is affected by a disturbance. By consulting with Slovnaft experts, we found that the resulting shift between measured and calculated values falls within the acceptable range for this process. In practice, partial material balances are carried out in similar cases to refine the data.

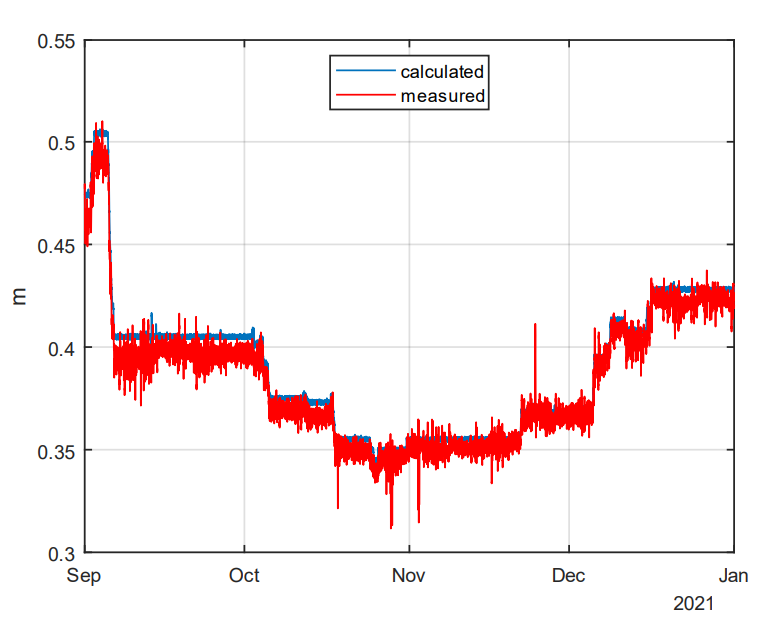

The calculated data have less noise, the waveforms are identical.

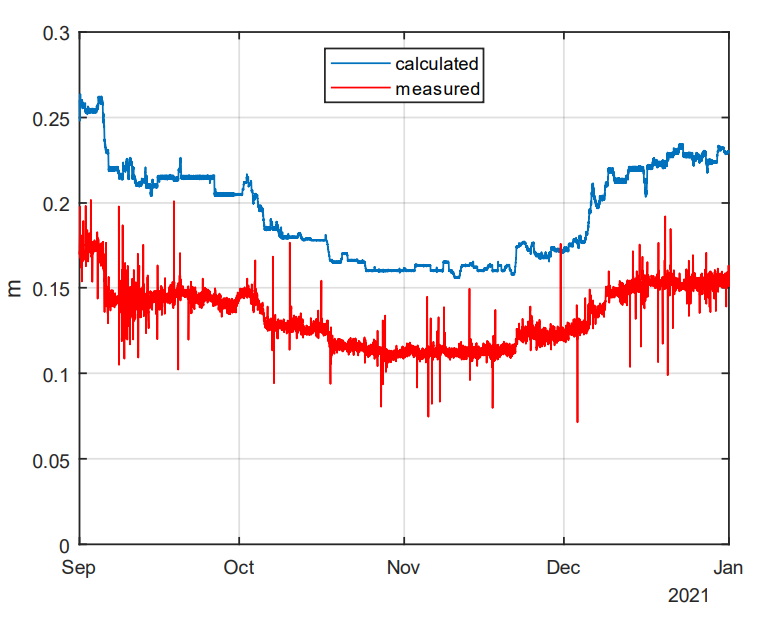

The calculated data have less noise. Shift in this range is within tolerance. A future goal of this project may be to detect anomalous behavior of the fault concentration analyzer.