This semestral project reflects the cooperation between our scientific group and intustrial partner.The goal is to design appropriate controller on our side to ensure suitable thermal conditions inside their battery energy storage system. The unsuitable thermal conditions lead to shorten lifespan, capacity, charging speed and performance in general. Right now, industrial partner uses conditional controller to command heating and ventilation system (HVAC) and fans inside batterry energy storage system to maintain the temperature inside predefined interval.

With a conditional controller, we observe oscillations between the upper and lower temperature limits, sometimes resulting in their violation. Therefore, our industrial partner’s requirement is to predict the future behavior of the system to avoid such issues. The advantages of Model Predictive Control are the ability to predict future system behavior based on a model and provide optimal control actions while considering constraints.

Initially, we focused on establishing a high-quality model. The resulting thermal model of the battery energy storage system considers the difference between incoming heat flows, including heat from the surroundings, HVAC, and heat generated by the battery power, and outgoing heat flows to the surroundings and HVAC.

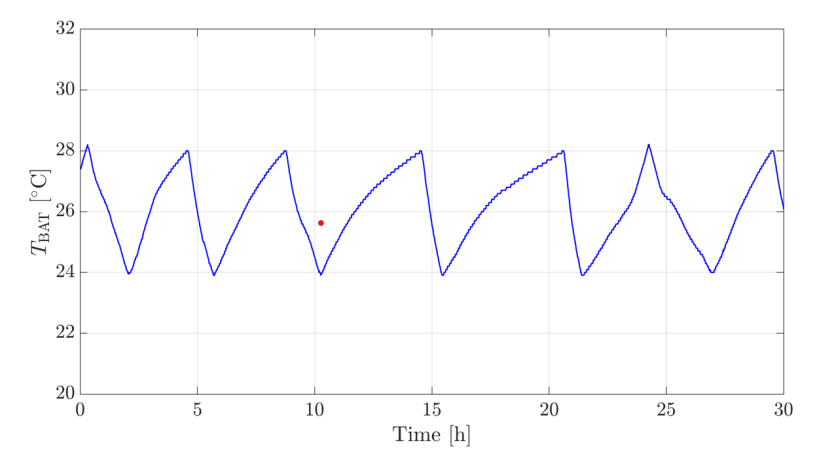

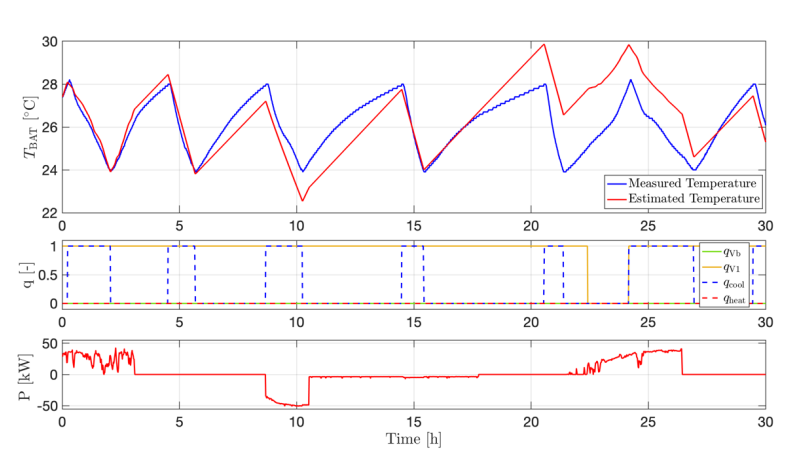

By comparing the model with the measured data (Figure 2), we have found that the model captures the dynamics quite well. We observed that the model can respond similarly to the system during both battery charging and discharging, as well as to active control elements. Finally, we designed MPC and obtained the results shown in Figure 3.

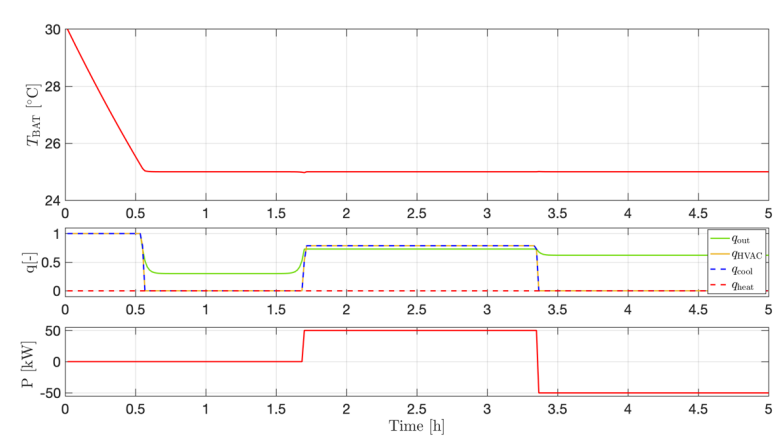

The graph (Figure 3) presents the results of temperature control simulation using MPC. During the simulation, we configured different power profiles for charging and discharging in the battery storage. Additionally, we set a constant ambient temperature of 15 °C. As we can see, despite the various changes, the battery temperature remained close to the desired reference.

The next step of this project will be real implementation and testing on industrial battery energy storage system, that is why we have implemented MPC algorithm in python environment and solved it with free IPOPT solver.